- Fundamentals of industrial warping technology

- Quantifiable impact on textile production efficiency

- Breakdown of modern warping machine capabilities

- Comparative analysis of leading equipment providers

- Custom engineering solutions for specialized operations

- Industry-specific implementation case studies

- Strategic considerations for equipment acquisition

(what is warping machine)

What is a Warping Machine? Unraveling the Basics

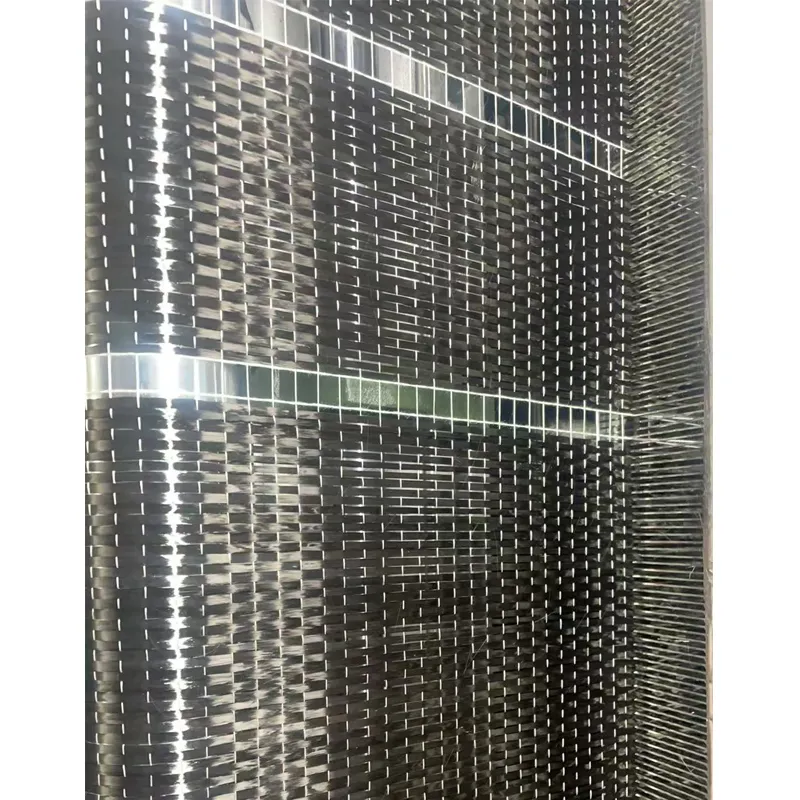

In textile manufacturing, warping machines transform individual yarns into parallel arrangements called warps – the fundamental backbone for weaving. These industrial systems transfer yarns from multiple packages onto section beams with uniform tension and precise alignment. As production prerequisites tighten globally, modern warping technology addresses critical demands: minimizing breakage rates (below 0.5% in premium models), accommodating 5-800 yarn ends simultaneously, and achieving operational speeds exceeding 1,200 meters/minute for synthetic fibers.

The Critical Role of Warping in Textile Manufacturing

Recent industry studies reveal warping operations consume 18-24% of total fabric production time, making efficiency paramount. Facilities adopting automated warping solutions report 34% higher throughput and 22% lower material wastage compared to manual processes. Productivity metrics demonstrate direct correlation between warping precision and downstream weaving efficiency: ±0.2% tension variation causes 7% weaving defects, while precision warping (<±0.1%) reduces fabric faults by 90%. The 2023 Global Textile Report indicates that warping optimization contributes 17% to overall mill profitability, impacting both economic and sustainability outcomes through material conservation.

Breakthrough Technologies Driving Modern Warping

Contemporary warping equipment incorporates revolutionary features that transform operations:

Intelligent tension control systems dynamically adjust pressure across 200+ yarns simultaneously using piezoelectric sensors

Machine learning algorithms predict breakage points with 94% accuracy by analyzing historical performance data

Eco-warper technology reduces energy consumption by 38% through regenerative braking systems

Robotic beam handling automatically transports 500kg beams between stations, eliminating manual labor

IoT integration enables remote monitoring with real-time tension mapping across production environments

Global Manufacturer Comparison Analysis

| Manufacturer | Production Speed (m/min) | Tolerance Control | Max Beam Load (kg) | Automation Level |

|---|---|---|---|---|

| Karl Mayer | 1,400 | ±0.07% | 1,200 | Full AutoDoFF |

| Benninger | 1,250 | ±0.09% | 1,000 | Semi-Auto |

| Tsudakoma | 1,100 | ±0.12% | 800 | Basic Auto |

| Jakob Mueller | 900 | ±0.15% | 750 | Manual |

Industry standard tolerances above 0.2% incur 7-12% weaving defect rates

Application-Centric Engineering Solutions

Leading warping machine manufacturers develop specialized configurations for diverse requirements:

Technical textiles - Heavy-duty ceramic tension discs for carbon fiber processing

Medical fabrics - ISO Class 7 cleanroom-compatible enclosures

Patterned weaving - Programmable tension profiling across beam width

Recycled materials - Anti-static systems for synthetic regeneration fibers

Micro-denier - Precision guide systems for filaments below 10dtex

Comprehensive technical support packages extend beyond installation, including vibration analysis training and digital twin simulations that model production outcomes before physical implementation.

Industry Implementation Scenarios

Automotive textiles: A European supplier achieved 99.3% defect-free airbag fabric by implementing radar-controlled tensioners that maintain 19cN ±0.5 accuracy during 3,000m runs.

Luxury apparel: A silk producer eliminated 87% of weaving faults using moisture-controlled environmental chambers integrated within the warping process.

Industrial fabrics: Conveyor belt manufacturers reduced yarn consumption 8% through precision sectional warping equipment configured for aramid fiber architectures.

Recent operational audits demonstrate facilities combining ultrasonic inspection with automated warpers achieved 99.1% first-pass quality validation - bypassing intermediate inspection stages while accelerating time-to-loom by 72%.

Selecting High-Performance Warping Machine Manufacturers

Evaluation criteria extend beyond technical specifications to comprehensive factors: manufacturing facility audits reveal top warping machine producers maintain tolerance calibration laboratories on-site with traceable measurement systems. Lifecycle cost analysis proves essential - machines commanding 15-20% premium typically demonstrate 60-70% operational savings over 5-year periods through energy efficiency and reduced maintenance. Partner selection should verify material compatibility testing protocols, specifically addressing synthetic fibers which require modified handling systems to prevent electrostatic disruption. The most effective partnerships combine engineering expertise with sector-specific knowledge, delivering both optimized warping machine textile solutions and continuous improvement programs aligned with evolving production demands.

(what is warping machine)

FAQS on what is warping machine

Q: What is a warping machine used for?

A: A warping machine prepares yarns for weaving by aligning multiple parallel yarn strands onto a beam. It ensures uniform tension and length across all yarns to create a warp beam. This process is essential for efficient fabric production.

Q: Why are warping machines important in textile manufacturing?

A: Warping machines directly impact fabric quality by preventing defects like uneven tensions or broken yarns during weaving. They enable high-speed transfer of thousands of yarns to warp beams. Modern textile factories rely on automated warping machines for mass production consistency.

Q: What factors should I consider when choosing warping machine manufacturers?

A: Prioritize manufacturers with proven industry experience and ISO certification. Evaluate technical specifications like max beam capacity, automation level, and compatibility with yarn types. Request case studies from textile mills similar to your operation.

Q: How do leading warping machine manufacturers ensure reliability?

A: Top manufacturers implement precision engineering with electronic tension control and automated fault detection systems. They conduct rigorous factory testing under simulated production conditions. Most offer technical support packages and modular upgrade paths for future needs.

Q: What innovations exist in modern warping machines?

A: Current models feature AI-driven tension monitoring and cloud-based performance analytics. Laser-based yarn break detection systems reduce waste by 30-50%. Direct drive motors and touchscreen interfaces have replaced mechanical controls for precision adjustments.