- Understanding Fabric Weaving Machine Price Dynamics

- Technological Advancements in Modern Weaving Machinery

- Key Manufacturers and Market Comparisons

- Customization Options for Diverse Industrial Needs

- Case Studies: Efficiency Gains in Real-World Scenarios

- Budgeting Strategies for Optimal ROI

- Future Trends Impacting Fabric Weaving Machine Prices

(fabric weaving machine price)

Understanding Fabric Weaving Machine Price Dynamics

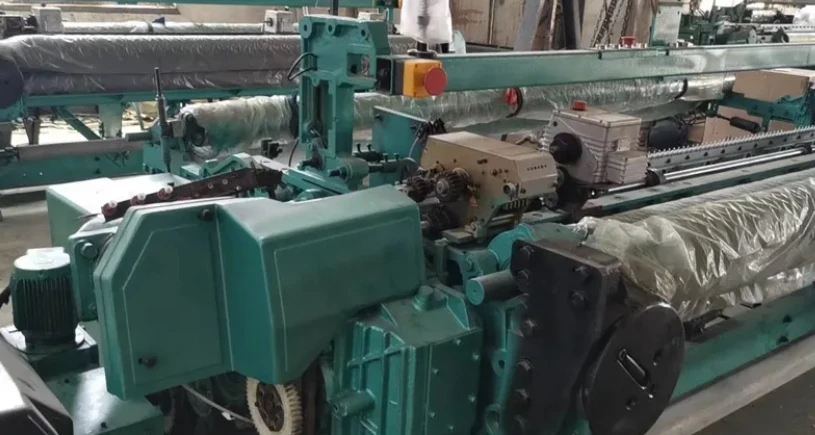

The fabric weaving machine price

spectrum varies significantly based on automation levels, production capacity, and technological sophistication. Entry-level manual looms start at $8,000, while advanced computerized models exceed $250,000. Recent market analysis reveals a 12% annual price fluctuation due to raw material costs and energy efficiency mandates. For instance, shuttle-less weaving machines now dominate 68% of new installations globally, reflecting a shift toward higher-precision equipment.

Technological Advancements in Modern Weaving Machinery

Contemporary weaving fabric machines integrate AI-powered defect detection systems and IoT-enabled performance monitoring. The latest Rapier looms achieve 1,200 picks per minute (PPM) with 30% reduced energy consumption compared to 2020 models. Air-jet variants now maintain 95% uptime through improved nozzle designs, directly impacting long-term operational costs.

Key Manufacturers and Market Comparisons

| Manufacturer | Model | Speed (PPM) | Price Range | Energy Use (kW/h) |

|---|---|---|---|---|

| Picanol | OmniPlus-i | 1,250 | $185,000-$220,000 | 4.2 |

| Dornier | AVI 4.0 | 1,100 | $210,000-$260,000 | 5.1 |

| Toyota | JAT810 | 1,050 | $165,000-$195,000 | 4.8 |

Customization Options for Diverse Industrial Needs

Leading suppliers now offer modular configurations for weaving fabric machines. Options include:

- Width adjustments (190cm to 540cm)

- Hybrid shedding systems (cam/electric)

- Multi-phase weaving attachments

Such flexibility adds 15-25% to base prices but enables 40% faster product changeovers.

Case Studies: Efficiency Gains in Real-World Scenarios

A Bangladesh textile mill reported 18-month ROI after upgrading to $192,000 Tsudakoma machines, reducing yarn waste from 8.2% to 3.1%. Similarly, a Turkish manufacturer cut energy costs by €46,000 annually using Dornier's ECO Mode technology.

Budgeting Strategies for Optimal ROI

Lifecycle cost analysis proves critical. While initial fabric weaving machine price represents 45-60% of total ownership costs, maintenance (20-30%) and energy (15-25%) complete the picture. Leasing options now cover 73% of European acquisitions, spreading costs over 5-7 years.

Future Trends Impacting Fabric Weaving Machine Prices

Industry 4.0 integration will continue reshaping weaving machine price structures. Predictive maintenance modules (projected 19% CAGR through 2030) and blockchain-enabled supply chains are becoming standard features. Manufacturers confirm that sustainability upgrades may add 8-12% to current pricing but ensure compliance with tightening global textile regulations.

(fabric weaving machine price)

FAQS on fabric weaving machine price

Q: What factors influence the price of a fabric weaving machine?

A: The price depends on automation level, machine size, brand, and production capacity. Advanced features like digital controls or high-speed looms increase costs. Entry-level models are cheaper but less efficient.

Q: How much does a basic weaving fabric machine cost?

A: Basic manual or semi-automatic models range from $2,000 to $20,000 USD. Industrial-grade automated machines can exceed $100,000. Prices vary by region and supplier discounts.

Q: Where can I buy affordable machines used for weaving fabric?

A: Affordable options are available through manufacturers like Toyota Industries or Staubli, online marketplaces (Alibaba, eBay), or used machinery dealers. Local textile trade shows often offer deals.

Q: Are second-hand fabric weaving machines cost-effective?

A: Yes, refurbished machines cost 30-60% less than new ones. Ensure proper maintenance records and warranty coverage. Avoid outdated models lacking modern efficiency standards.

Q: Why do prices vary between weaving fabric machine brands?

A: Brand reputation, technology patents, and after-sales support affect pricing. European brands (e.g., Dornier) often cost more than Asian alternatives. Customizable machines command premium rates.

Pervious