The Fiberglass Mosquito Net Machine represents a cutting-edge solution in the manufacturing of fiberglass mesh products. Designed for industrial applications, this system integrates advanced technologies to produce high-quality mosquito nets, window screens, and other mesh-based materials. Developed by Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer in the field, these machines combine durability, efficiency, and precision to meet modern production demands.

Core Features and Functionalities

The Fiberglass Mosquito Net Machine is a comprehensive production line that includes multiple specialized components, each designed to optimize specific stages of the manufacturing process. Key elements of this system include:

- Fiberglass Yarn PVC Coating Machine: This machine applies PVC resin to glass fiber yarn, enhancing its tensile strength and surface quality. The process involves four grinding tools and two heating stages to ensure uniform coating and meet production requirements for window yarn.

- Warping Machine: Divided into one-time molding and strip warping models, this machine ensures even tension and arrangement of glass fiber yarn on the warp shaft, preparing it for weaving. The 260 Type model, for instance, features a magnetic powder brake, photoelectric protection, and an advanced control system.

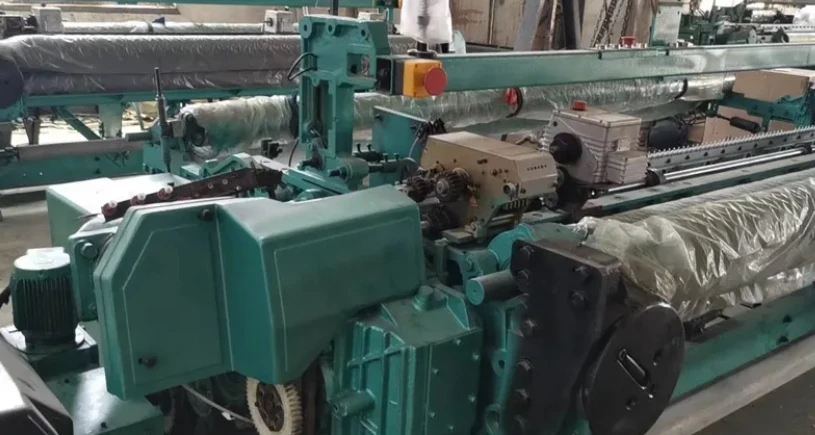

- Weaving Machine: Equipped with upgraded technology, this machine produces flat mesh surfaces with clear textures and square mesh patterns. The 260 Type model operates at 135-165 cycles per minute, ensuring high production efficiency.

- Coating Machine: After weaving, the mesh undergoes high-temperature shaping to bond the warp and weft yarns, improving strength and aesthetics. This machine has a 320-meter-long design with 4 ovens, achieving a production rate of 2000-2200 meters per hour.

- Mesh Quality Inspection Machine: This device monitors mesh length and density, ensuring compliance with specifications. It can support up to 8 weaving machines and features a 2.2 kW electric motor.

Technical Specifications and Performance Metrics

The Fiberglass Mosquito Net Machine is engineered to deliver exceptional performance, as evidenced by its detailed technical specifications:

| Machine Type | Dimensions | Power | Weight | Speed | Key Advantages |

|---|---|---|---|---|---|

| Fiberglass Yarn PVC Coating Machine | 26m x 2m x 1.8m | 18 kW | N/A | 800 kg/24h (28-30 threads) | High tensile strength, smooth surface, and efficient coating |

| Warping Machine (260 Type) | L4.2m x W1.75m x H1.25m | 15 kW | 2 tons (excluding yarn rack) | 800-1200 m/h | High stability, automation, and uniform warp tension |

| Weaving Machine (260 Type) | L4.2m x W1.8m x H1.45m | 1.5 kW | 1.8 tons | 135-165 cycles/min | Flat mesh, square pattern, and high efficiency |

| Coating Machine | 320m x 32m x 4.5m | 220 kW | N/A | 2000-2200 m/h | Enhanced strength, durability, and aesthetics |

| Mesh Quality Inspection Machine | 3100x920x1550mm | 2.2 kW | 500 kg | N/A | Accurate monitoring of mesh length and density |

Applications and Industry Relevance

The Fiberglass Mosquito Net Machine is widely used in the production of mosquito nets, window screens, and industrial mesh products. Its applications span across residential, commercial, and industrial sectors, offering solutions for:

- Residential Use: High-quality mosquito nets and window screens that provide effective pest control and ventilation.

- Commercial Use: Durable mesh products for large-scale facilities, such as warehouses and agricultural greenhouses.

- Industrial Use: Customized mesh solutions for machinery, filtration systems, and safety equipment.

The machine's ability to produce meshes with precise specifications, such as 14x17, 16x18, and 20x20, ensures versatility for diverse customer requirements. According to the National Institute of Standards and Technology (NIST), "standardized manufacturing processes are critical for ensuring product consistency and performance in industrial applications." This aligns with the Fiberglass Mosquito Net Machine's design, which emphasizes precision and reliability.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Founded in 2005, Anping Hongke Wire Mesh Machinery Factory has established itself as a leader in the production of industrial mesh machinery. Located in Anping County, Hebei Province, China, the company specializes in providing advanced solutions for fiberglass mesh and mosquito net manufacturing. With a focus on innovation and quality, Anping Hongke has earned a reputation for delivering durable, efficient, and cost-effective machinery.

The company's commitment to excellence is reflected in its state-of-the-art facilities and rigorous quality control processes. As highlighted by NIST, "manufacturers that prioritize precision and standardization are better positioned to meet global market demands." Anping Hongke's adherence to these principles ensures that its products meet international standards and customer expectations.

Advantages and Competitive Edge

The Fiberglass Mosquito Net Machine offers several advantages that set it apart from traditional manufacturing methods:

- Enhanced Durability: The PVC coating process significantly improves the tensile and flexural strength of glass fiber yarn, ensuring long-lasting performance.

- Efficiency: With high-speed operations and automated systems, the machine maximizes productivity while minimizing labor costs.

- Customization: The ability to produce meshes in various sizes and specifications allows for tailored solutions to meet specific client needs.

- Cost-Effectiveness: By reducing material waste and energy consumption, the machine offers a sustainable and economical production option.

Conclusion

The Fiberglass Mosquito Net Machine is a testament to the advancements in industrial manufacturing. Its integration of cutting-edge technology, precision engineering, and user-friendly design makes it an ideal choice for businesses seeking reliable and efficient solutions. As noted by NIST, "innovation in manufacturing processes is essential for driving economic growth and technological progress." Anping Hongke Wire Mesh Machinery Factory continues to lead in this domain, delivering products that meet the evolving needs of the industry.

References

National Institute of Standards and Technology (NIST) (2025). "Standardized Manufacturing Processes for Industrial Applications." Retrieved from https://www.nist.gov.