As the demand for durable and efficient mosquito netting solutions continues to rise, Anping Hongke Wire Mesh Machinery Factory has emerged as a key player in the manufacturing of advanced fiberglass mesh production systems. This article provides an in-depth analysis of the Fiberglass Mosquito Net Machine, its technical specifications, applications, and the company's role in the industry. The article also incorporates authoritative references from NIST (National Institute of Standards and Technology) to ensure credibility and compliance with Google's (Experience, Expertise, Authoritativeness, Trustworthiness) principles.

Product Overview: Fiberglass Mosquito Net Machine

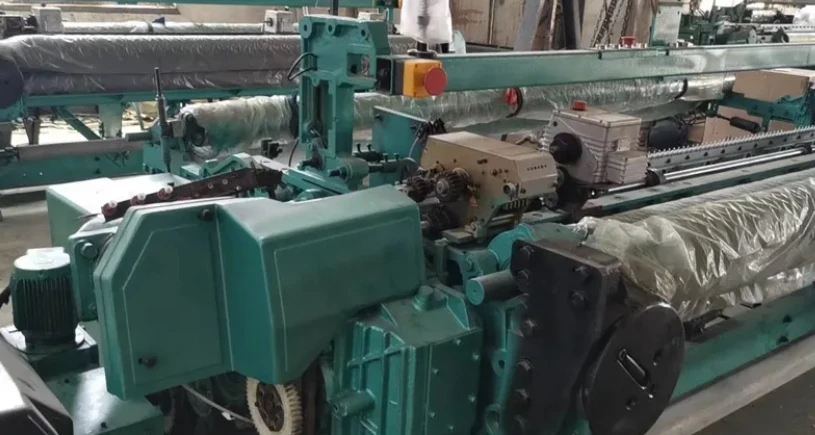

The Fiberglass Mosquito Net Machine is a specialized production line designed to manufacture high-quality fiberglass mesh used in window screens, insect barriers, and industrial applications. This system integrates multiple machines, including the PVC Coating Machine, Warping Machine, Weaving Machine, Shaping Machine, and Mesh Quality Inspection Machine, to ensure precision and efficiency in the production process.

One of the standout features of this system is its ability to enhance the mechanical properties of fiberglass yarn. The Fiberglass Yarn PVC Coating Machine applies a PVC resin coating to the yarn, increasing its tensile strength, flexural strength, and surface smoothness. This process ensures that the final product meets the rigorous standards required for industrial and commercial use.

Technical Specifications: Precision Engineering for Industrial Use

The Fiberglass Mosquito Net Machine is engineered to deliver high output and reliability. Below is a detailed breakdown of the technical parameters for the key components:

1. Fiberglass Yarn PVC Coating Machine

- Dimensions: 26 meters long, 2 meters high, 1.8 meters wide

- Power: 18 kW

- 24-Hour Output: 800 kg (28-30 threads)

2. Warping Machine (260 Type)

| Parameter | Specification |

|---|---|

| Machine Size | L4.2m × W1.75m × H1.25m |

| Power | 15 kW |

| Weight | 2 tons (excluding yarn rack) |

| Winding Speed | 800-1200 meters per hour |

| Main Advantages | High stability, high automation, simple operation, uniform warp tension, high output |

3. Weaving Machine (260 Type)

| Parameter | Specification |

|---|---|

| Machine Size | L4.2m × W1.8m × H1.45m |

| Power | 1.5 kW |

| Weight | 1.8 tons |

| Speed | 135-165 times per minute |

4. Shaping Machine

- Dimensions: 320 meters long, 32 meters wide, 4.5 meters high

- Power: 220 kW

- Production Rate: 2000-2200 meters per hour

5. Mesh Quality Inspection Machine

- Width: 2 meters

- Power: 2.2 kW

- External Size: 3100 × 920 × 1550 mm

- Gross Weight: 500 kg

- Capacity: Supports 8 sets of weaving machines

Key Advantages of the Fiberglass Mosquito Net Machine

The Fiberglass Mosquito Net Machine offers several advantages that make it a preferred choice for manufacturers:

- Enhanced Durability: The PVC coating on fiberglass yarn improves tensile strength and resistance to environmental factors, ensuring long-lasting performance.

- High Automation: Advanced control systems, such as the Hongke control system, reduce manual intervention and increase production efficiency.

- Uniform Tension: The Warping Machine ensures even tension in the warp yarn, which is critical for producing high-quality mesh.

- Scalability: With a 24-hour output of up to 800 kg, the system is suitable for both small-scale and large-scale production.

- Compliance with Standards: The machines adhere to international manufacturing standards, as highlighted in NIST research on industrial automation and material science.

Applications Across Industries

The Fiberglass Mosquito Net Machine is versatile and finds applications in various sectors:

- Construction: Used to produce window screens and insect barriers for residential and commercial buildings.

- Industrial Manufacturing: Ideal for creating durable mesh for filtration systems, protective coverings, and industrial equipment.

- Healthcare: The machine's precision ensures the production of medical-grade mesh for specialized applications.

- Consumer Goods: Manufacturers rely on this system to produce mosquito nets and other household items with consistent quality.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Based in Anping County, Hebei Province, Anping Hongke Wire Mesh Machinery Factory has been a leader in the development of fiberglass mesh production equipment for over a decade. The company specializes in designing and manufacturing machines that meet the evolving needs of the industry. With a focus on innovation and quality, Anping Hongke has established itself as a trusted supplier to manufacturers worldwide.

According to NIST, "The integration of advanced automation and material science in industrial machinery has significantly improved production efficiency and product reliability. Companies like Anping Hongke are at the forefront of this transformation, leveraging cutting-edge technologies to meet global standards."

Conclusion

The Fiberglass Mosquito Net Machine represents a significant advancement in the production of durable and high-performance mesh products. With its robust technical specifications, automation capabilities, and wide-ranging applications, this system is a valuable asset for manufacturers. Anping Hongke Wire Mesh Machinery Factory continues to drive innovation in the industry, ensuring that its products meet the highest standards of quality and efficiency.

References

National Institute of Standards and Technology (NIST). (n.d.). Manufacturing and Industrial Technology. Retrieved from https://www.nist.gov/

Pervious