The Vital Role of Fiberglass Mesh Warping Machines in Textile Manufacturing

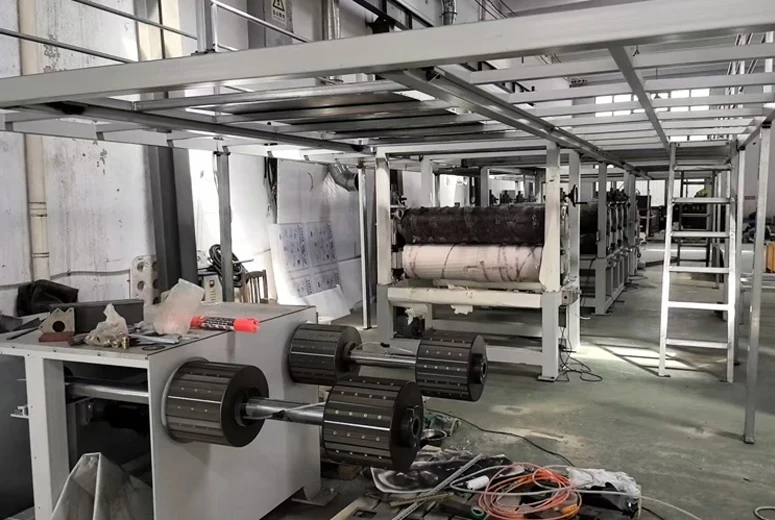

At Anping Hongke Wire Mesh Machinery Factory, we have been pioneering wire mesh production equipment since 2008, with our machines serving industries across Egypt, Turkey, India, Russia and beyond. Among our specialized machinery lineup, the Fiberglass Mesh Warping Machine stands as a cornerstone technology for preparing fiberglass yarns before the weaving process. This critical piece of equipment ensures the precise alignment and tension control necessary for producing high-quality fiberglass mesh products.

Understanding the Fiberglass Mesh Warping Machine

The Fiberglass Mesh Warping Machine performs the essential function of arranging hundreds or thousands of fiberglass yarns in parallel formation with consistent tension before they are transferred to the weaving loom. Unlike conventional textile warping, fiberglass presents unique challenges due to its brittle nature and sensitivity to tension variations. Our machine addresses these challenges through specialized design features that protect the delicate yarns while maintaining production efficiency.

Modern warping machines for fiberglass incorporate advanced electronic controls that monitor and adjust yarn tension in real-time, preventing breakage and ensuring uniform yarn distribution. The precision of this process directly impacts the quality of the final woven product, making the warping stage arguably the most critical preparation step in fiberglass mesh manufacturing.

Key Features of Advanced Warping Machine Technology

Contemporary Fiberglass Mesh Warping Machines from Anping Hongke integrate several technological innovations to handle the demanding requirements of fiberglass processing. The machines feature specially designed creels that minimize yarn contact points to reduce friction and static buildup. Advanced tensioning systems employ microprocessor controls to maintain optimal tension across all yarns simultaneously, compensating for any variations that could affect weaving quality.

Another significant advancement is the incorporation of automatic defect detection systems. These sophisticated sensors can identify broken or misaligned yarns during the warping process, allowing for immediate correction before the yarns proceed to weaving. This level of quality control significantly reduces material waste and improves overall production efficiency.

Applications and Industry Significance of Fiberglass Mesh Warping Machines

The prepared warp beams from our Fiberglass Mesh Warping Machine serve numerous industrial applications. In construction, they become the foundation for fiberglass reinforcement mesh used in concrete and stucco applications. For industrial filtration systems, the precision-warped yarns create mesh products with exacting pore sizes for liquid and air filtration. The electronics industry relies on these machines to produce the fine mesh used in printed circuit board manufacturing.

Perhaps most importantly, the warping process enables the production of fiberglass mesh with consistent mechanical properties throughout the entire roll. This uniformity is critical for applications where material performance must meet strict engineering specifications, such as in aerospace composites or ballistic protection materials.

Technical Considerations in Warping Machine Operation

Operating a Fiberglass Mesh Warping Machine requires careful attention to several technical parameters. Yarn tension must be precisely calibrated based on the specific fiberglass composition and yarn count. The machine speed must be optimized to balance production efficiency with yarn integrity maintenance. Environmental factors like humidity and temperature also play crucial roles, as fiberglass yarns can be sensitive to moisture absorption and static electricity buildup.

Modern machines address these challenges through automated control systems that adjust parameters in real-time. Some advanced models even feature self-learning algorithms that optimize settings based on the characteristics of each yarn batch, significantly reducing setup times between production runs.

For manufacturers looking to enhance their fiberglass mesh production capabilities, investing in a high-quality warping machine from a trusted supplier like Anping Hongke can significantly improve product quality and production efficiency. Contact us today to learn how our warping solutions can benefit your fiberglass manufacturing operations.